The chilling rate after slaughter is a critical part of producing meat that is of high quality and safe to eat. From a shelf life and food safety perspective, carcases should be chilled as quickly as possible however from an eating quality perspective, fast chilling can cause cold-toughening. So with meat processing the optimal chilling rate represents a balance between the control of microbiological growth and meat tenderness.

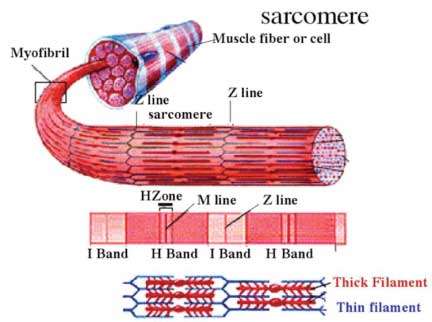

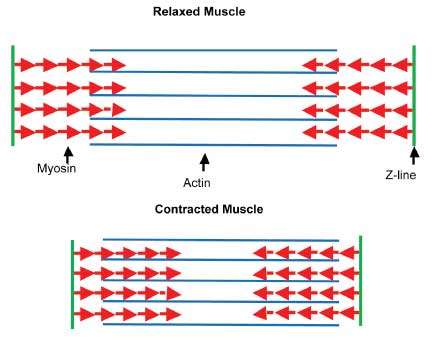

With conventional chilling systems, meat becomes tough due to cold shortening when the chilling rate is too fast. Meat is made up of fibres that are bundled together and held intact by sheaths of connective tissue (Figure 1). These fibres are made up of the proteins actin and myosin that are linked together in an ordered structure. These proteins are responsible for muscle contraction in the live animal whereby the actin and myosin filaments move in relation to each other as shown in Figure 2.

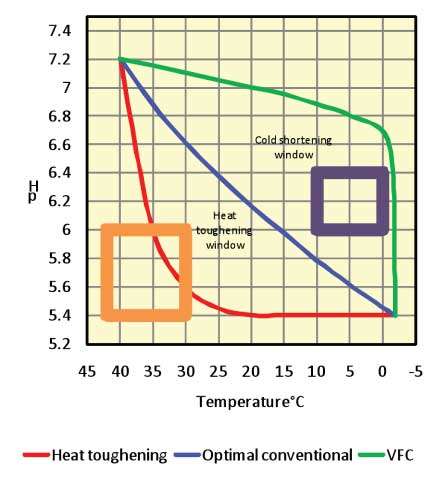

If the muscle temperature drops below 10oC, before rigor onset occurs, calcium floods out of the sarcoplasmic reticulum (an intracellular structure that regulates calcium levels in the cell, controlling the degree of contraction) and the muscle contracts. During rigor, the actin (thin filament) and myosin (thick filament) elements become linked by chemical bonds that once formed prevent the filaments moving against each other, making the muscle inextensible (rigor). Contracted muscle has more bonds between the actin and myosin filaments making the meat tough to eat. Cold shortening, as this phenomenon is known, is the most important cause of toughness in meat derived from young animals, in which the effect of connective tissue is small. It occurs when the temperature of the meat drops below 10°C while the pH is above 6. The risk of cold shortening can be assessed by measuring pH and temperature during chilling (Figure 3) as is routinely done during grading for Meat Standards Australia. The paradox with very fast chilling is that cold shortening does not occur despite the temperature being well below 10°C before rigor onset.

How Fast is Very Fast

Chilling is called ‘very fast’ when muscle temperature is reduced from 40°C in the live animal to below 0°C within 5 hours of slaughter. By comparison the target for carcase meat cooled conventionally is 10°C about 10 hours after slaughter; although in practice this target varies according to other processing factors such as electrical stimulation. The rate of rigor onset can be accelerated by changing the rate of glycolysis and acid formation within the muscle using electrical stimulation. This means that the pH drops more quickly in electrically stimulated carcases than in non-stimulated carcases, and this allows the cooling rate to be increased while still achieving optimal pH-temperature conditions.

With VFC the temperature is effectively reduced to the point of freezing and this needs to be done before rigor commences. European researchers first investigated VFC in the 1990s for the purpose of increasing carcase yield. They reported that VFC sometimes resulted in tender meat, but a high proportion of product was not tender and this lack of consistency prevented adoption by the European industry.

How Does VFC Work

VFC is a concept still under development but research done in the last 5 years has provided useful information about the potential to apply this idea to a commercial application. Work has been done with lamb and beef in laboratory and commercial scenarios using a range of cooling systems. This work has established that VFC is different to conventional chilling in several ways:

1. Cold shortening is prevented even when the meat is hot boned

2. Tenderisation occurs faster than with normally chilled meat but the reasons for this are unknown

3. The rate of pH decline post mortem is faster

4. Ultimate pH may be higher

5. Yield is improved

6. Electrical stimulation is compatible with VFC

7. Increased opportunity to batch chill and avoid mixing hot meat with cold meat

The importance of meat temperature reaching sub-zero temperatures before rigor onset has been a key finding. If this benchmark is not reached then severe cold shortening causes meat to be tough and unstable in colour when cut and displayed for retail sale.

How Can Very Fast Chill Rates Be Achieved

VFC can be achieved using a number of different methods including air, plate and immersion chilling systems. Each method has advantages and disadvantages that need to be taken into account for the type of production system applied. The temperature of the cooling medium depends on the chilling method used but in all cases will be well below 0°C. For immersion and plate systems specialised packaging may be required to allow rapid heat transfer.

Another key aspect is the thickness of the material being chilled. For VFC, meat should not exceed 80 mm in thickness otherwise chilling rate becomes limited by the rate of heat transfer within the meat. This consideration means that hot boning is an essential component of VFC when used to process beef and larger smallstock carcases.

Why Chill Very Fast

VFC is likely to be applicable to specialised applications rather than being a mainstream alternative to conventional chilling. VFC has already been used to process meat for sausage making. Situations where VFC may be considered would include:

- Hot boning applications

- Renovations to increase throughput without increasing chilling space

- New plant designs where low capital cost is paramount

- Prevention of the detrimental effects of heat toughening

Acknowledgements

Dr Robin Jacob – Department of Agriculture and Food WA, Perth

Cooling meat to below 0°C within 5 hours of slaughter is defined as very fast chilling (VFC)

VFC can avoid cold shortening

VFC can improve yield and the rate of tenderisation

VFC is best applied to light-weight carcases or hot-boned meat

Figure 1: The actin (thin filament) and myosin (thick filament) structure of muscle

Figure 2: The relationship of actin and myosin in relaxed and contracted muscle

Figure 3: pH temperature profile of meat during chilling for heat toughening, conventional and VFC scenarios

REPRODUCED FROM MEAT TECHNOLOGY UPDATE 4/11 WITH PERMISSION FROM CSIRO, MLA, AMPC AND DAFWA

BRAHMAN NEWS SEPTEMBER 2011 Issue #172