- Hormonal growth promotants (HGPs) increase cattle growth rates and carcase size. Different compounds are used for heifers and steers, to work in conjunction with natural hormones.

- Marbling scores can be reduced.

- The use of HGPs can result in detectible reductions in tenderness.

- When combined with a Brahman content of >50%, the adverse effects on tenderness can be increased.

- As with non-treated carcasses, some of the adverse effects of HGPs on tenderness can be limited by ageing, tenderstretching and ensuring the MSA pH/temperature window is met.

Hormonal growth promotants (HGPs) are used extensively in northern Australia and the feedlot industry. They are used to a lesser extent in southern Australia and are banned in Tasmania. HGPs are used to improve the rate of liveweight gain and the feed efficiency of cattle by producing a hormone that is very similar in structure to the animal’s natural hormone. In excess of 2.5 million doses are sold annually in Australia and of these about half are used in pasture-fed steers in northern Australia. The industry currently uses a wide range of HGPs that can be implanted at the different stages of production such as at weaning, at backgrounding on pasture and at entry to the feedlot. The implants can have a functional life of up to 400 days and contain either oestrogenic or androgenic compounds or combinations of both.

The increase in liveweight due to HGP implants is well documented with an increase in liveweight gain of 10-20 kg over 100 to 150 days. However the effect on meat quality is less clear. Some studies have found that the use of HGPs leads to tougher meat but others have found little effect or that the increased toughness is so slight as to be not commercially significant. A series of trials has been completed by scientists at the Beef Co-operative Research Centre (CRC) and MSA to document the effect of different HGP dosage strategies on weight gain and meat quality.

GROWTH RATE

HGP treatment can result in significant improvement in growth rate of both pasture-fed and lot-fed cattle. In one trial, pasture-fed steers administered an implant every 100 days were on average about 7.5% heavier than non-implanted steers after periods of up to 671 days. There was an advantage to implanted steers during periods of moderate weight gain (~0.75 kg/day) but when pasture was poor and there was static or very slow growth, there was no advantage to the implanted steers. In a commercial situation, however, animals would not be re-implanted every 100 days, so the weight gains reported are unlikely to be achieved.

There is a greater benefit from HGP implantation when cattle are growing quickly such as during lot feeding. The effect of the implant also increases with time with greater differences in weight between implanted and non-implanted cattle as time on feed increases. In one trial, implanted cattle fed to Korean weight specifications gained 6.7% more while those fed for the Japanese market gained 7.2% more. Steers responded better than heifers to the implants gaining almost twice as much as heifers. But, in this trial, steers and heifers were given different HGP formulations and so direct comparisons cannot be made.

CARCASE CHARACTERISTICS

Along with the increase in live weight due to HGP treatment, there is a corresponding increase in dressed carcase weight. HGP implanted carcases also have a higher ossification score but a 10 to 15% lower marbling score. The reasons for reduced marbling scores are unclear. Some have proposed that implantation early in an animal’s life could delay the deposition of marbling, whereas others consider that it is due to the stimulation of increased protein deposition which effectively dilutes the fat content within the muscle. A recent study in the U.S. found that implantation did not have a direct effect on intramuscular lipid deposition, whereas others determined that implanted cattle should be slaughtered at a higher body weight to achieve the same marbling score as non-implanted cattle. The higher ossification scores give the impression of a carcase that is more mature for its age than one that has not been hormone treated.

HGP implantation has no effect on dressing percentage, therefore an overall increase in carcase weight leads to in an increase in weight of saleable meat. Subcutaneous fat depth and ultimate pH are not affected by HGP implantation, but intramuscular fat (marbling) was decreased.

The ‘aggressive’ use of HGPs has been shown to increase the stress susceptibility of cattle resulting in an increase in dark-cutters. Provided the implants are conducted strictly according to directions, there should be minimal effect on meat colour. Allowing a period of at least 100 days between implantation and slaughter should minimise the effects on meat colour.

MEAT QUALITY

Most studies have shown that there is a measureable decrease in eating quality of beef from animals that have been implanted with hormonal growth promotants. This has been revealed through both objective measurements (Warner-Bratzler shear force) and by the results of sensory measurements using consumer panels.

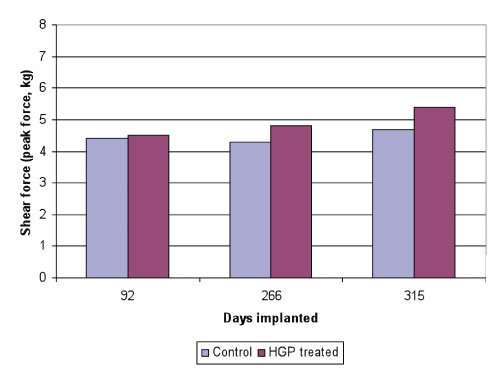

Increases in shear force due to HGP treatment were greater the longer the animal had been on the implantation program (Hunter, 2001). Feedlot-finished cattle implanted for 92 days and fed for the domestic market did not have a significantly higher shear force than non-implanted cattle, whereas those implanted for over 300 days and prepared for the Japanese market were significantly tougher (Figure 1). The study indicated that this is not an effect of water-holding capacity: HGP treatment had no effect on quantity of fluid lost during cooking.

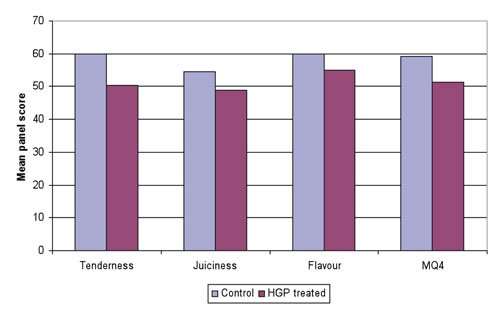

Furthermore, consumer panels were able to detect differences between meat from untreated cattle and meat from HGP treated animals. For example Angus steers that had been HGP implanted and lot fed for 55 days had lower sensory scores (considered to be less acceptable) for the M. longissimus dorsi (LD) than similar non-implanted steers that had been on the same feed regime. The differences in tenderness, and overall composite score were highly significant as shown in Figure 2.

A statistical analysis of the combined results from 30 different international HGP treatment-control comparisons on beef also showed that HGP treatment had a negative effect on beef palatability in all but 3 experiments. These studies appeared in refereed journals dating back as far as 1956. This ‘meta-analysis’ showed that the effect of HGP implantation is to increase the shear force for the LD by 0.27 kg and to reduce tenderness by 5.4 points on a 100-point scale.

Meat scientists disagree on the reasons for this reduced palatability but a favoured theory is that the results are consistent with reduced protein degradation, possibly as a result of increased calpastatin activity in the live animal resulting in lower ageing rates post slaughter and less tender meat. HGP treatment is known to increase protein synthesis and reduce degradation, resulting in more muscle growth.

FIGURE 1: Effect of HGP treatment on shear force of M. longissimus dorsi (Hunter et al, 2001)

FIGURE 2: Consumer panel scores for LD muscle (adapted from Thompson et al, 2008a)

EFFECT ON OTHER MUSCLES

The majority of researchers concentrate on the Longissimus or loin muscle when assessing the effects a process may have on meat quality, but this muscle is not always indicative of the effects on other valuable cuts. Trials, which have included six different muscles from beef carcases, have shown that HGP treatment can have significant detrimental effects on the tenderness scores of the M. longissimus dorsi (striploin and cube roll) and the M. biceps femoris (silverside) but little or no effect on the tenderness of the M. gluteus medius (rump), M. psoas major (tenderloin), M. triceps brachii (blade) or the M. infraspinatus (oyster blade).

Generally, it appears that muscles that show the greatest tenderness improvement during ageing are the most affected by HGP implantation and vice versa. The striploin and silverside show significant improvement in tenderness during ageing for 14 days while the other primals such as the tenderloin, rump and blade show little if any improvement in eating quality between aging for 5 days and 21 days. This is consistent with the theory that HGP implantation increases calpastatin and those muscles with the highest calpain to calpastatin ratio (or greatest ageing rate) would have the greatest response to HGP application and therefore, potentially the greatest impact on post-mortem tenderness. The increase in calpastatin slows the ageing rate resulting in less tender meat from those muscles that improve most during ageing.

EFFECT ON BRAHMAN CATTLE

Cattle with a high proportion of Bos indicus appear to respond differently to cross-bred Bos taurus cattle to the implantation of HGPs. In a study involving a total of 478 B. indicus and B. indicus x B. taurus cross steers, carcases from cattle with 100% B. indicus were 19 kg lighter, and had lower marbling scores than those with 50% B. indicus. Implantation with oestradiol-17β resulted in a 17-kg overall increase in carcase weight relative to the non implanted controls.

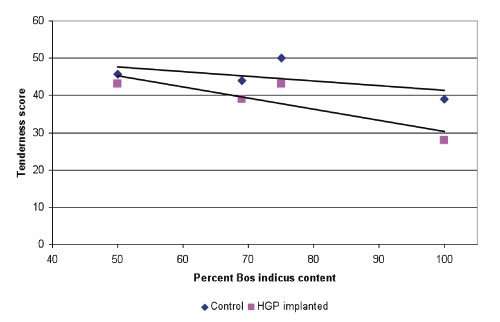

As the percentage B. indicus content increases above 50%, the decrease in consumer scores for tenderness due to HGP treatment becomes more pronounced as can be seen in Figure 3. HGP implantation appears to acts synergistically to produce even tougher meat from the cattle with high B. indicus content. Meat from implanted cattle with high B. indicus content can be very tough unless steps are taken to ensure the meat is more palatable. It is known that meat from B. indicus cattle has increased calpastatin activity and decreased tenderness compared with meat from B. taurus cattle. It is assumed that the combination of B. indicus and HGP treatment result in a lower protein turnover rate and consequently tougher meat.

FIGURE 3: Bos indicus content and HGP treatment on tenderness (adapted from Thompson et al, 2008b)

IMPLANTATION STRATEGIES

A wide range of HGP programs involving different promotants and implantation times can be used to improve the growth rate of cattle. HGPs are generally implanted at the time of other cattle management activities such as weaning, transport to a backgrounding property, during backgrounding, and at entry to a feedlot. Is it more detrimental to meat quality to implant HGPs at all of these stages of production or only at weaning and feedlot entry?

Implants are normally based on either the female hormone oestrogen or the male hormone androgen or a combination of the two. They can be naturally occurring hormones or synthetic such as the androgenic compound trenbolone acetate (TBA). TBA is often used in combination with an oestradiol compound for finishing steers and heifers.

In a large experiment, several proprietary HGPs containing oestrogenic or androgenic compounds or a combination of the two were implanted at different stages of production. There appeared to be no difference in carcase weight or other carcase quality characteristics between implanting heifers twice and implanting them three times and also no differences noted between the HGPs tested, although there were only small numbers of animals in each treatment group. Neither were there any differences in sensory scores for meat from the different treatment strategies. There were some small differences in weight gain between treatment strategies for steers but little apparent difference in meat quality among the different strategies. All implant treatments gave poorer tenderness scores than the non-HGP controls.

SAFETY OF HGPS

Although the European Union will not accept meat from animals that have been treated with hormones, it has been acceptable to many other markets for over 50 years. HGPs have been used in Australia since 1979. The main concern to consumers is the level of oestrogen and its possible effect on adolescents and the foetus, which can be sensitive to small increases in hormone levels. Concern has also been expressed regarding the carcinogic effect of oestradiol to humans as it stimulates cell division thereby increasing the possibility of random errors during DNA duplication.

Residues from hormone implants are higher in internal organs such as livers than in the muscle of cattle. When heifers had received three or four implants containing the synthetic androgenic hormone TBA, the mean concentration of 17 alpha-trenbolone in the livers was 4.3 ng/g when slaughtered 30 days after implantation. The concentration of 17 beta-trenbolone in the muscle was less than 0.4 ng/g. The Australian Pesticides and Veterinary Medicines Authority has set a maximum residue limit (MRL) of 0.002 mg/kg (2.0 ng/g) for TBA. The natural level of testosterone in meat from steers was determined in Germany to be in the range <0.01-0.14 ng/g. The mean level of the oestrogen-like compound 17β-Estradiol was measured at <0.04 ng/g.

Oestradiol, testosterone and progesterone are naturally present in many foods of animal origin and some of plant origin. It has been estimated that a person would need to consume 77 kg of beef from HGP-treated steers to receive the same amount of oestrogen as eating one hen egg.

COUNTERING THE EFFECTS OF HGPS

It appears that HGP treatment of cattle can result in measureable reductions in palatability of beef, especially in the case of cattle with a significant Brahman content. There are several options that the processor can take to ensure acceptable eating quality of the meat from implanted cattle.

- Meat from HGP-treated animals does not improve as quickly during ageing, so an additional period may be required. For example, cuts such as the striploin and silverside should be aged for at least 3 weeks.

- Tenderstretching (hanging by the aitch bone or sacrosciatic ligament) during chilling has been shown to provide great improvement in the tenderness of certain primal cuts. This will largely offset the effects of HGP treatment.

- Carcase chilling and electrical stimulation should be managed to provide the optimum rate of pH/temperature fall so that the MSA Window is met.

FROM MEAT TECHNOLOGY UPDATE AUGUST 2009

BRAHMAN NEWS SEPTEMBER 2009 Issue #164